Exploring the Advantages of Membrane Layer Switches for Modern Electronic Devices

The expedition of membrane layer buttons in contemporary electronic gadgets offers a fascinating point of view on their myriad advantages, particularly in terms of layout flexibility, longevity, and cost-effectiveness. As markets proceed to develop, the function of membrane switches in boosting customer experience and functional efficiency warrants more detailed evaluation.

Benefits of Membrane Layer Switches

Membrane buttons are progressively preferred in contemporary electronic devices due to their countless advantages. Among the primary benefits is their compact design, which enables space-efficient integration right into different gadgets. This slim account not only conserves area but likewise adds to the total visual charm of digital products.

An additional advantage is their longevity. Membrane layer buttons are typically resistant to dampness, dust, and pollutants, making them perfect for use in environments where exposure to extreme conditions is a problem. This resistance expands the lifespan of the switches, reducing the need for frequent replacements and upkeep.

In addition, membrane switches over deal excellent responsive responses, improving individual experience. The tactile action is usually made to give a satisfying experience upon activation, which can improve individual fulfillment and performance.

Additionally, the production process of membrane switches is cost-effective, enabling for lower production costs compared to traditional mechanical buttons. This affordability makes them ideal for a vast variety of applications, from consumer electronic devices to commercial machinery.

Design Versatility and Modification

The layout versatility and modification alternatives supplied by membrane switches additionally improve their appeal in modern electronics. These switches can be tailored to fulfill certain aesthetic and useful needs, enabling manufacturers to develop gadgets that align carefully with brand name identity and individual choices. With different choices in regards to shades, forms, and sizes, membrane layer buttons can perfectly integrate into diverse item styles, whether for consumer electronics, commercial applications, or medical devices.

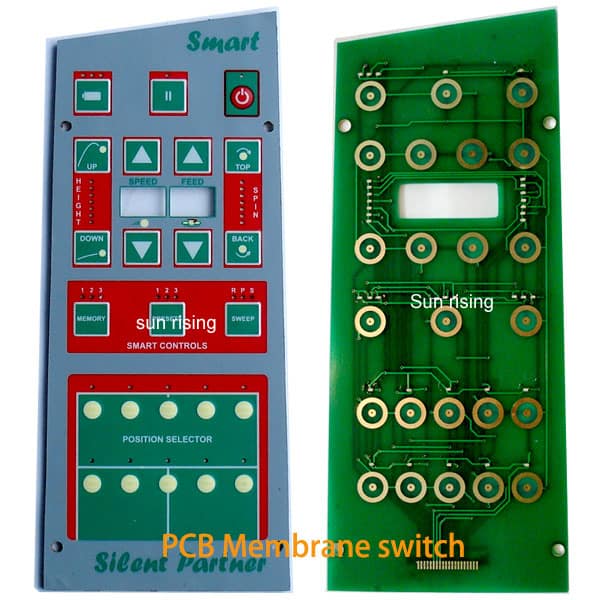

Moreover, the capacity to integrate graphics and icons straight onto the switch surface area boosts usability while minimizing the need for additional labeling. This combination not only streamlines manufacturing procedures yet likewise adds to a sleeker total appearance. The layout can be additional personalized with attributes such as backlighting, responsive feedback, and multi-layer building and constructions, offering improved user interaction.

Longevity and Ecological Resistance

In addition, membrane switches can be crafted to be chemically immune, making them suitable for applications in industrial atmospheres where exposure to solvents and cleaning up agents prevails. The encapsulation of digital elements within the membrane layer framework provides extra protection versus environmental tensions, guaranteeing reliable efficiency even in tough problems.

Along with physical toughness, membrane layer switches over exhibition outstanding resistance to UV light, stopping destruction and discoloration in time (membrane switch). This characteristic is specifically helpful for exterior applications, where prolonged direct exposure to sunlight can compromise various other button kinds

Eventually, the toughness and environmental resistance of membrane layer switches make them an optimal selection for a vast array of contemporary digital devices, from clinical tools you can try these out to consumer electronic devices, making certain consistent performance and user complete satisfaction throughout different applications.

Cost-Effectiveness in Manufacturing

Cost-effectiveness in manufacturing is a significant advantage of membrane layer buttons, making them a recommended option for manufacturers in different industries. The manufacturing process of membrane layer changes commonly involves fewer products contrasted to traditional buttons, which lowers basic material costs. This streamlined production procedure not just conserves money but likewise decreases waste, straightening with contemporary sustainability objectives.

In addition, membrane layer switches can be generated using automated techniques, allowing for high-volume outcome with decreased labor expenses. The combination of advanced printing modern technologies additionally improves effectiveness, allowing manufacturers to achieve detailed styles and capabilities without sustaining considerable extra expenses. This scalability makes sure that manufacturing can adjust to altering market needs without jeopardizing quality or increasing expenses.

In addition, the light-weight nature of membrane switches over adds to set you back savings in delivery and handling, along with in the overall layout of electronic devices. By getting rid of bulky parts, suppliers can optimize the general item layout, consequently improving market competition. Overall, the cost-effectiveness of membrane layer changes not only benefits producers economically but also assists in innovation and quick item development in the dynamic landscape of contemporary electronic devices.

Applications in Various Industries

Versatility stands apart as a hallmark of membrane layer switches, enabling them to find applications throughout a vast array of industries. In the healthcare market, these buttons are essential to clinical devices, providing easy to use user interfaces for devices like infusion pumps and analysis machines. Their resistance to wetness and easy cleaning make them suitable for settings needing rigorous hygiene standards.

In the auto sector, membrane More about the author buttons add to the functionality of control panels and control panels, offering a smooth, modern appearance while ensuring longevity versus extreme problems. Their lightweight design likewise sustains total lorry performance.

Furthermore, industrial equipment utilizes membrane switches for functional controls. Their robust nature and personalized attributes try this out accommodate the certain needs of diverse applications.

Verdict

Finally, membrane layer switches over deal significant advantages for modern-day electronic devices, consisting of style versatility, resilience, and cost-effectiveness. membrane switch. Their customizable features and resistance to environmental factors make them suitable for a wide variety of applications throughout different industries. As technical needs remain to advance, the flexibility and efficiency of membrane layer switches over setting them as an essential part in enhancing customer experience and driving advancement within the competitive landscape of digital devices